We have four cars in our household and three of them are more than 10 years old. They all have engine management lights showing. The trouble is, the engine management light doesn’t tell you what the actual fault is – it’s just a warning to tell you something’s up. To help understand the problem you need to interrogate the car’s control system, known as the ECU (Engine Control Unit) by reading the fault codes.

Knowing I could buy a code scanner to help decipher the conditions behind these fault codes I bought one and began looking into the cause of the errors on cars which were otherwise running just fine!

In the process I picked up a little of the jargon in the code scanner world. A few key terms follow, to demystify this area of vehicle ownership.

OBD-II - On Board Diagnostics 2. A standard pretty much all cars now follow as it was made mandatory for all cars manufactured in the US since 1996.

MIL - Malfunction Indicator Lamp. The scary yellow light (or sometimes orange or red light depending on the severity of the fault) which appears on the dashboard as an engine symbol.

DTC - Diagnostic Trouble Code. Alphanumeric codes OBD-II scanners display once plugged in and connected to your vehicle. They are split into 4 categories (Power, Chassis, Body and User Network) followed by a number of digits further describing the fault (e.g. P0215).

It’s worth noting: although OBD-II is a standard it isn’t necessarily the end of the story. Many car manufacturers add functionality into their diagnostic systems in addition to the standard OBD-II facilities available.

So how do you use an OBD-II Scanner? Simply plug it into the OBD connector, normally found somewhere behind the trim on the driver’s side by the dashboard, and it should spring into life.

My scanner is a very simple one (it cost me £36 from Amazon). It starts reading data immediately it is plugged into the car, presenting a menu from where I can interrogate the car’s status. Even the simplest scanners will enable you to read fault codes and reset them and also show live engine data such as engine speeds, mass air flow etc. More expensive units show graphs of live data too. The most expensive scanners allow you to manipulate the cars settings, termed bidirectional control.

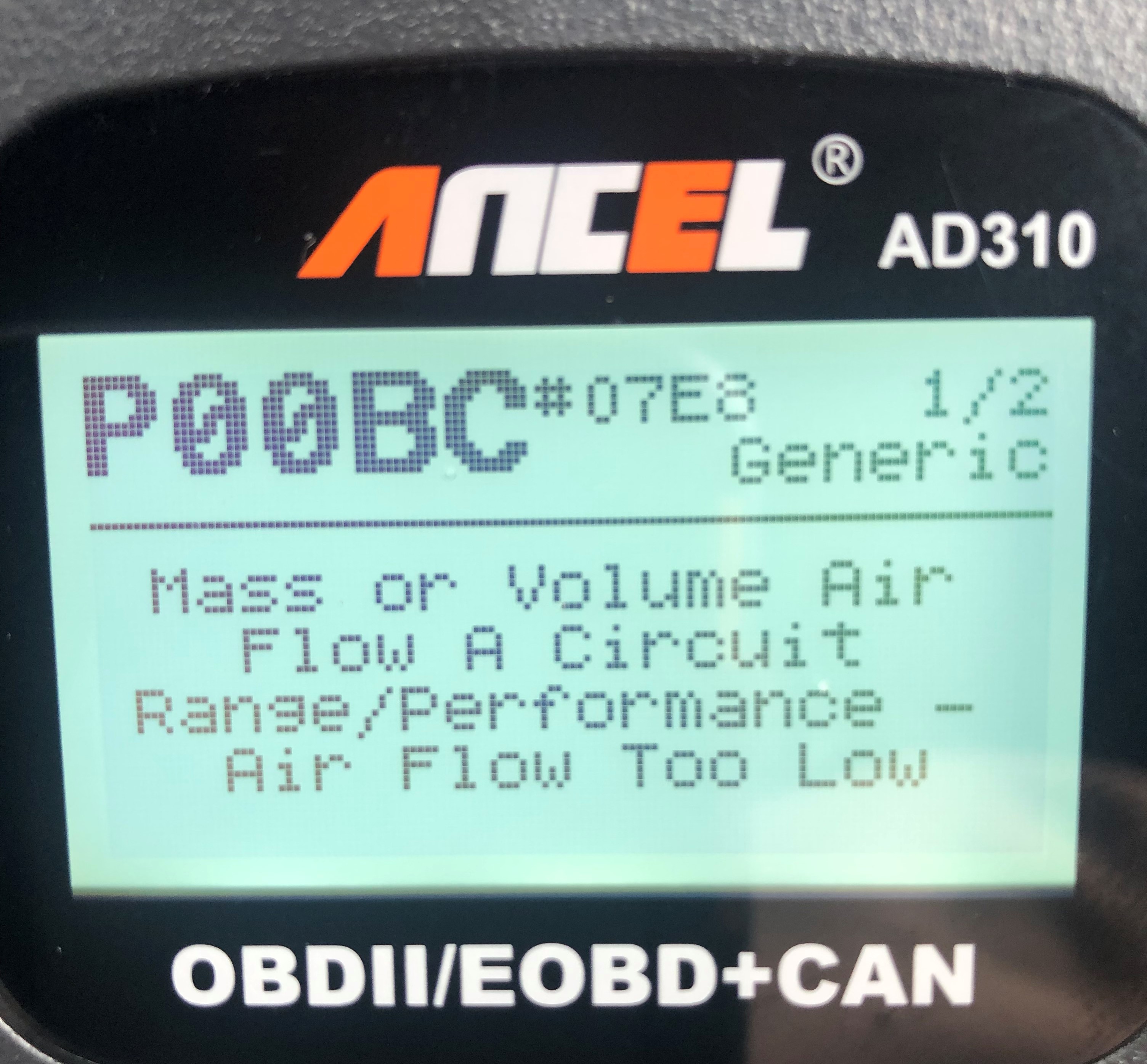

I first tried the scanner on my daughter’s car, the photo below shows the code displayed. I quickly worked out why they are called “codes”! ‘Mass or Volume Air Flow A Circuit Range/Performance – Air Flow too Low’ didn’t really tell me exactly what was wrong. It did point us in the right direction though. On further examination the fault was found to be a blocked pipe which cost £26.00 to fix.

I expect you’re hoping for a punchline to this article. Well in my mind its what you can come to understand by using diagnostic systems and how they can save you money. It’s interesting to observe the motor industry providing advanced diagnostic systems to consumers, while many manufacturers supplying the very same industry remain reluctant to adopt similar technology. Systems such as SCADAs and Process Historians can be used to diagnose faults and better understand how to run a plant at maximum efficiency.

So my punchline (or moral to the story) is to advocate you implement a diagnosis system to drive (pun intended) process optimisation in your company. Get past measuring success by not breaking down and move to being able to predict failures and tune the performance of your equipment. Develop a diagnostic system which provides a clear visualisation of everything happening in your plant. Then alerts you when something needs attention and how to correct it - before it goes wrong!