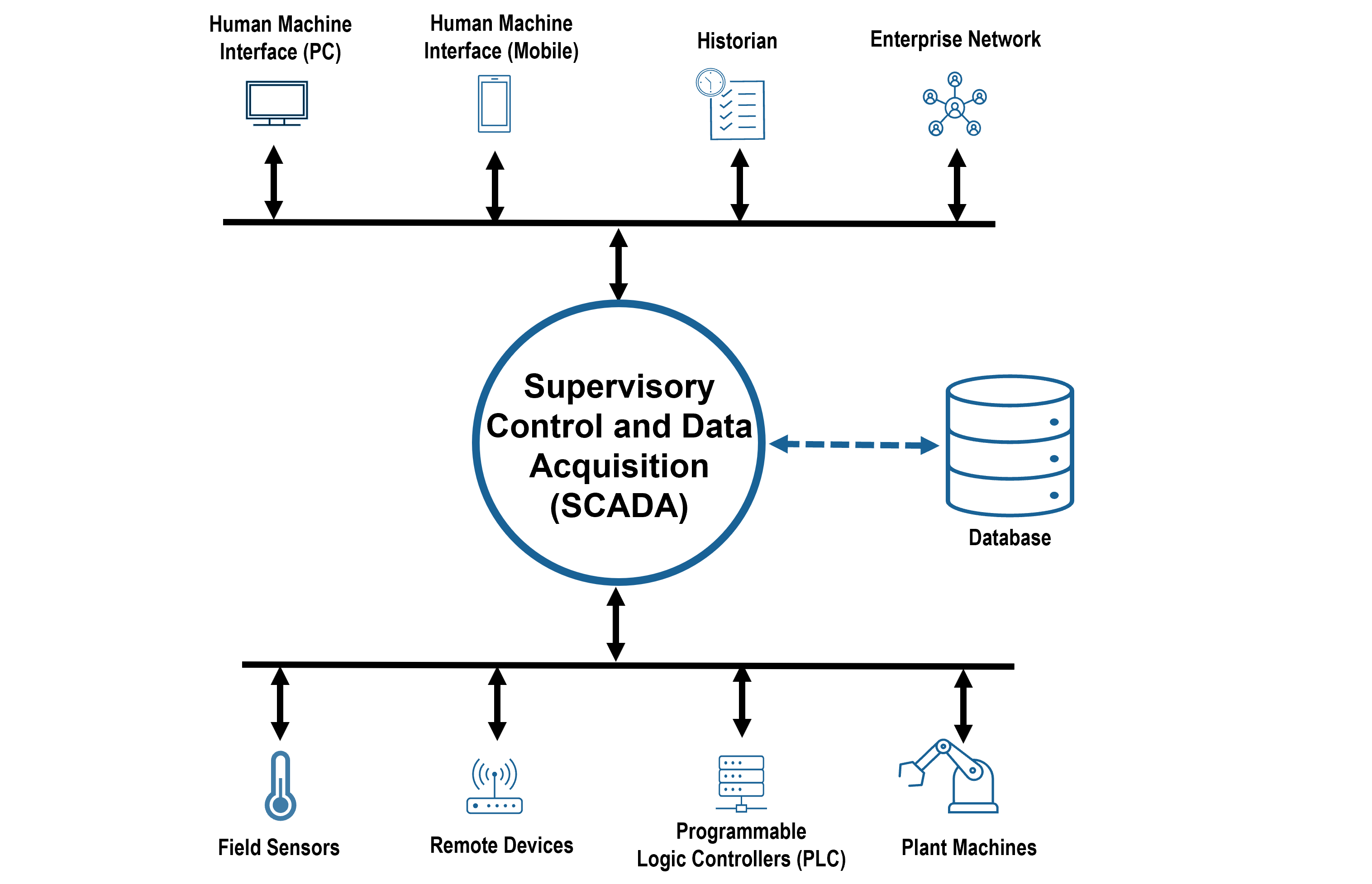

SCADA systems are used to collect process data, display plant status information, and provide users with control over automated processes. SCADA systems are highly configurable, able to provide a wide variety of monitoring and control functions to the diverse roles which make up an operational workforce.

Key Technologies

SCADA systems make use of proprietary database technology and/or open platforms such as SQL.

Commonly the user interface often referred to as the HMI (Human Machine Interface) comprises a screen hierarchy where the plant is split into logical areas. For example, a tank farm feeding a chemicals manufacturing facility would be displayed on one screen and the process vessel reactors on other screens while common services and utilities on further screens. For a chemical plant each screen resembles a PI&D (Piping and Instrumentation Diagram) where instruments, motors and valves etc are also included.

To collect data from plant-level Operational Technology (OT) SCADA systems make use of open industrialised protocols like OPC and MQTT, as well as being compatible with proprietary communications utilised by specialised or legacy systems.

Process information is made available to Information Technology (IT) via application programming interfaces, accessed using methods such as SQL, OData and ODBC.

Benefits

Visualisation and Control – Access to real-time plant conditions via fixed operator displays and mobile devices. Remote control and optimisation of automated processes.

Reporting – Scheduled and event driven reports deliver time-sensitive information to users via email, text message or device notifications. Alert operations staff to process conditions, maintenance staff to potential equipment failures and keep management up-to-date on operational performance.

Historian – Plant data is able to be both recorded and archived using SCADA systems. In this respect the SCADA system acts as a data repository with search and analysis features.

For more information follow the link below to the Services section of our website where you can learn more about the help we can offer on this topic and many others relating to industrial process and manufacturing automation.