Many industrial applications can benefit from the use of Variable Speed Drives (also known as Variable Frequency or Inverter Drives). The increased motor control VSDs provide can improve product quality, and reduce energy consumption.

Key Technologies

Most automation vendors offer VSDs. Market leaders such as ABB and Siemens have wide product portfolios to suit the needs of every type and size of application. VSD technology is well established and involves input power (AC) is rectified and is then switched (either in single or 3 phase configurations) to supply the motor windings. This switching determines the motor frequency feeding the motor windings which in turn determines the motor speed.

Benefits

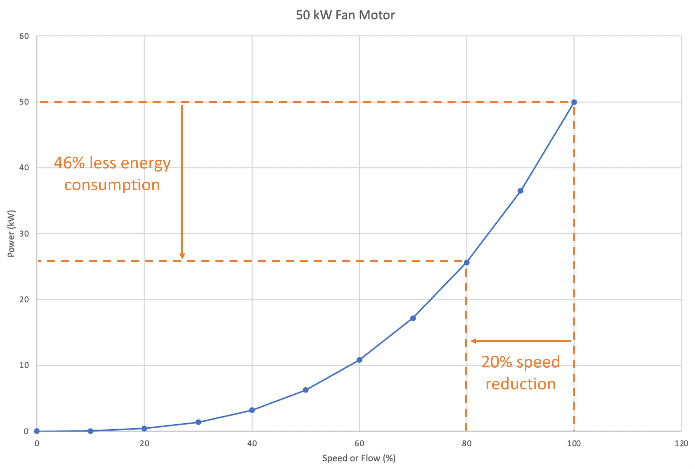

Variable torque applications such as pumps and fans typically have the most scope for reducing energy consumption. In these applications more energy is required to drive increased air or fluid flow as motor speed increases. This relationship is demonstrated in the power curve for an example 50kW fan motor (shown). In many situations, motors are oversized to allow for peak demand meaning that in normal operation the motor is running at a higher speed demanded by the process. This is sometimes exacerbated by mechanical throttling of the motor with some form of restriction such as a damper or throttle valve in order to control the air or fluid flow at a fixed rate (analogous to driving your car on the motorway with one foot on the accelerator and with the other foot on the brake to control the speed). By controlling the motor to run at slower speeds and by removing any unnecessary restriction then a drastic reduction in energy consumption can be achieved.

VSDs don’t only have the advantage of being able to control motor speeds but are also able to provide other advantages such as soft starting and, if fitted with suitable filtering systems can also reduce the effects of harmonics across the electrical network. The fact VSDs can be incorporated in closed loop control systems means processes can also be optimised. Another benefit of using VSDs is the motor bearings and associated hardware is less prone to stress and is therefore far more likely to operate over extended periods and with reduced maintenance. In short there really aren’t any disadvantages to introducing VSDs to your site except perhaps the initial capital costs. However, the payback periods can easily be calculated based on the energy savings which simply depend upon the reduced duty and reduced speeds that would be implemented following installation.

For more information follow the link below to the Services section of our website where you can learn more about the help we can offer on this topic and many others relating to industrial process and manufacturing automation.