Automation systems used to control batch processes typically feature a ‘Batch Engine’. This software is commonly seen in industries like fine chemicals and pharmaceuticals. Control systems featuring batch engines differ from those used in continuous processes; they follow ‘recipes’ to manufacture discrete quantities of product.

Key Features

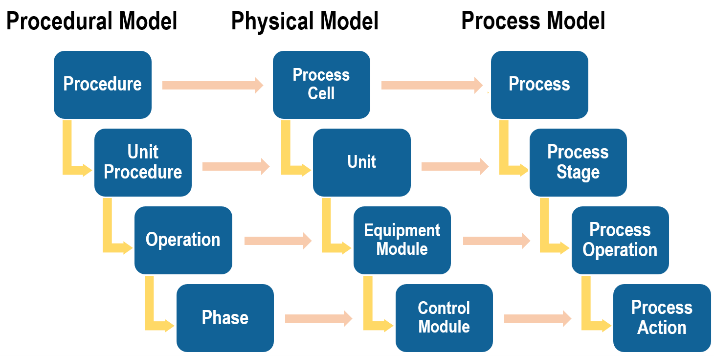

The batch engine at the heart of batch control systems coordinates plant equipment using software models and rules defined in the ANSI/ISA88 standard – commonly referred to as ‘S88’. The S88 standard features a physical model, used to identify how plant and equipment fits into the wider enterprise. The procedural model is then used to define the software which utilises control equipment to control the process during a recipe. While most Distributed Control Systems provide S88 compliant batch systems, stand-alone batch engines are also available for SCADA-PLC solutions.

Benefits

Batch systems enable multiple products to be manufactured using shared equipment increasing utilisation of the plant. The ‘modularisation’ of a production area, combined with software logic which acquires plant components on behalf of recipes can make it possible to run multiple batches through plants concurrently.

Logging and auditing features make traceability of raw materials into finished product automatic. Most have comprehensive reporting tools enabling quality control and process optimsation. In time recipes can be optimised based on data on energy and raw materials consumption, processing time, and quality (including the integration of lab results where available).

Designing new and modifying existing recipes within batch systems is relatively simple compared with reconfiguring continuous control systems. This means personnel without a background in automation can configure the system according to their requirements without specialist help.

Recipes can be designed to fully automate production, guide manual operation, or anywhere in between. This means batch systems provide flexibility and control over processes which either cannot be easily automated or aren’t fully developed (prototypes or proof of concepts).

Batch systems support the digitalisation of businesses by enabling the conversion of existing processes and logs into electronic forms. The systems will support electronic signing and authentication requirements within the food and pharmaceutical industries.

For more information follow the link below to the Services section of our website where you can learn more about the help we can offer on this topic and many others relating to industrial process and manufacturing automation.