We all have a favourite t-shirt, sweater, pair of jeans or trainers that have stood the test of time - in our own eyes at least. Comfortable, dependable and reliable, we only feel compelled to replace these items when they finally fall apart in the wash, or someone close to us takes drastic action and disposes of them on our behalf.

If it ain't broke...

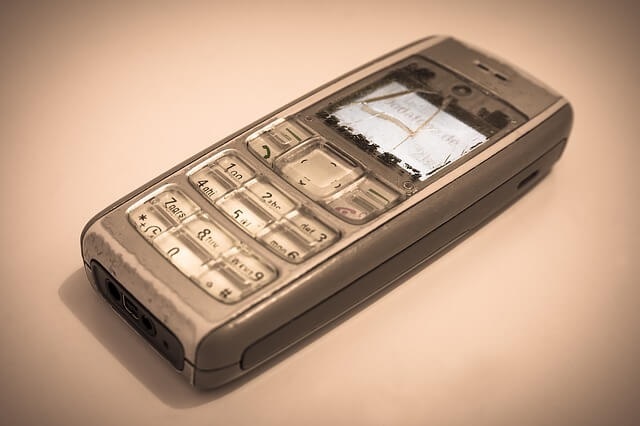

But when it comes to technology, the mantra "if it ain't broke, don't fix it" no longer seems to apply. The decision to replace something no longer feels like ours to make: smartphone, tablet or laptop not compatible with the latest operating system? You "need" to upgrade before the risks of running unsupported software become too great, or to access the latest applications and features. A fear of falling behind, too often justifies an upgrade we could have put off. My new jeans never seem to offer more features than my last.

Those able to resist the urge to upgrade seem to be rewarded, a better model offering more for less emerges a few months later to the frustration of those who couldn't wait. In the meantime, the world didn't end because their activity tracker was a little more chunky, their phone couldn't record HD video, or smartwatch needlessly replicate every annoying Facebook notification (just me?).

... don't panic!

Whether you're at the cutting edge, or manage with last years model at home; the latest technology is a luxury many working on established process and manufacturing sites can only dream of. When it comes to ageing control systems different rules apply, upgrades are costly and come with a fair degree of risk. That said, having given good service over the years, so-called legacy systems become increasingly difficult to maintain:

- OEMs increasingly struggle to offer the level of service required as experienced engineers retire

- Spares are getting expensive, and suffer from extended lead times

- Reporting and monitoring requirements bring pressure to connect systems to enterprise networks, further exposing them to security threats

Your current vendor may offer a migration path to their latest system, and the justification is probably there. But is this the best option for your site? Would you like to evaluate the alternative options?

We can help

Having worked with many of the major DCS, PLC and SCADA systems, both old and new, Op-tec will give you impartial advice. If required, we can reverse engineer your existing system to produce a requirement specification for a current generation system.

However in many cases it is possible to prolong the life of existing technology, and plan the phased replacement or upgrade of existing systems over time, scheduling work during routine shutdowns.

As an independent service provider it is not in our interests to recommend expensive solutions where not required, or 'make things easy' with an initially attractive rip-and-replace strategy that risks disrupting ongoing production.