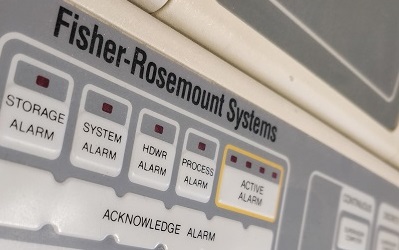

The Rosemount System 3 (RS3) DCS can still be found controlling a variety of industrial processes today, after first being installed in 1984. If you're still using RS3 you've likely benefitted from many years of trouble-free service from a system that doesn't need a lot of routine maintenance. For this reason the justification for putting off migration to a newer control system has been easy.

Emerson Automation Solutions withdrew on-demand support for the RS3 DCS in October 2013. Since then Emerson have only offered factory support via a 'Sustain Program' designed to migrate users onto their DeltaV platform. If you're still running RS3 equipment you're saving money by delaying the inevitable upgrade project, and avoiding the frequent updates modern Windows-based systems require to remain secure and supportable. This can make the costs for replacing RS3 look prohibitively expensive, however the time will come when this is no longer the case.

Op-tec Systems has supported customers with RS3 equipment for over 20 years. While many choose Emerson to migrate their system to DeltaV, there is an alternative. In the short term we can support you in continuing to use RS3 as your main DCS. In the medium-long term this isn't something we can recommend due to the availability of spare parts and personnel with the necessary expertise and experience. Our preferred approach is a phased migration of the system, to an up-to-date PLC-SCADA or DCS solution.

If the most pressing reason for replacing your RS3 DCS is availability of HMI components. We have solutions to most challenges, having given many aging systems a new lease of life, restoring performance to ‘as new’. One example is a converter which allows the use of off-the-shelf USB pointing devices with RS3 consoles, shown below.

We're also able to provide replacement keyboards and connect the latest industrial and panel PC's to RS3. Upgrades like this also move you onto open protocols, meaning new equipment will be compatible with modern control systems and can be retained when you come to upgrade.

Because while RS3 components were built to last their proprietary nature means there's limited ways to integrate it efficiently with modern systems.

Essentially, your RS3 DCS is made up of:

- Operator Consoles

- ControlFiles, with Card Cages (holding I/O modules)

- Interfaces to external systems

These components communicate via a redundant PeerWay communications highway. RS3 is capable of controlling continuous and batch processes, via Rosemount Basic Language (RBL) programming and later ABC Batch Studio.

Emerson can offer migration to their latest technology incrementally, while other major vendors tend to recommend an 'all or nothing' rip and replace approach.

We can help plan a RS3 replacement, by reverse engineering the programming of your current system, evaluating your needs and likely future requirements and supplying a lifecycle management plan for a phased, incremental migration; or FEED study if you'd prefer to replace your system in one go. Our reverse engineering services save significant amounts of redesign and specification work.

While you continue to run RS3 equipment we can provide service support, giving you the reassurance of having engineering expertise available as and when you need it. Our development systems are also available to test spares and validate backup files.

If you would like to speak to one of our engineers about your RS3 installation, to understand the options available to you, get in touch.